Utilisation

CHP EXTENSIONS

agriKomp offers you customised energy concepts for CHP applications. We develop

optimised CHP units with modern engine technology from renowned manufacturers.

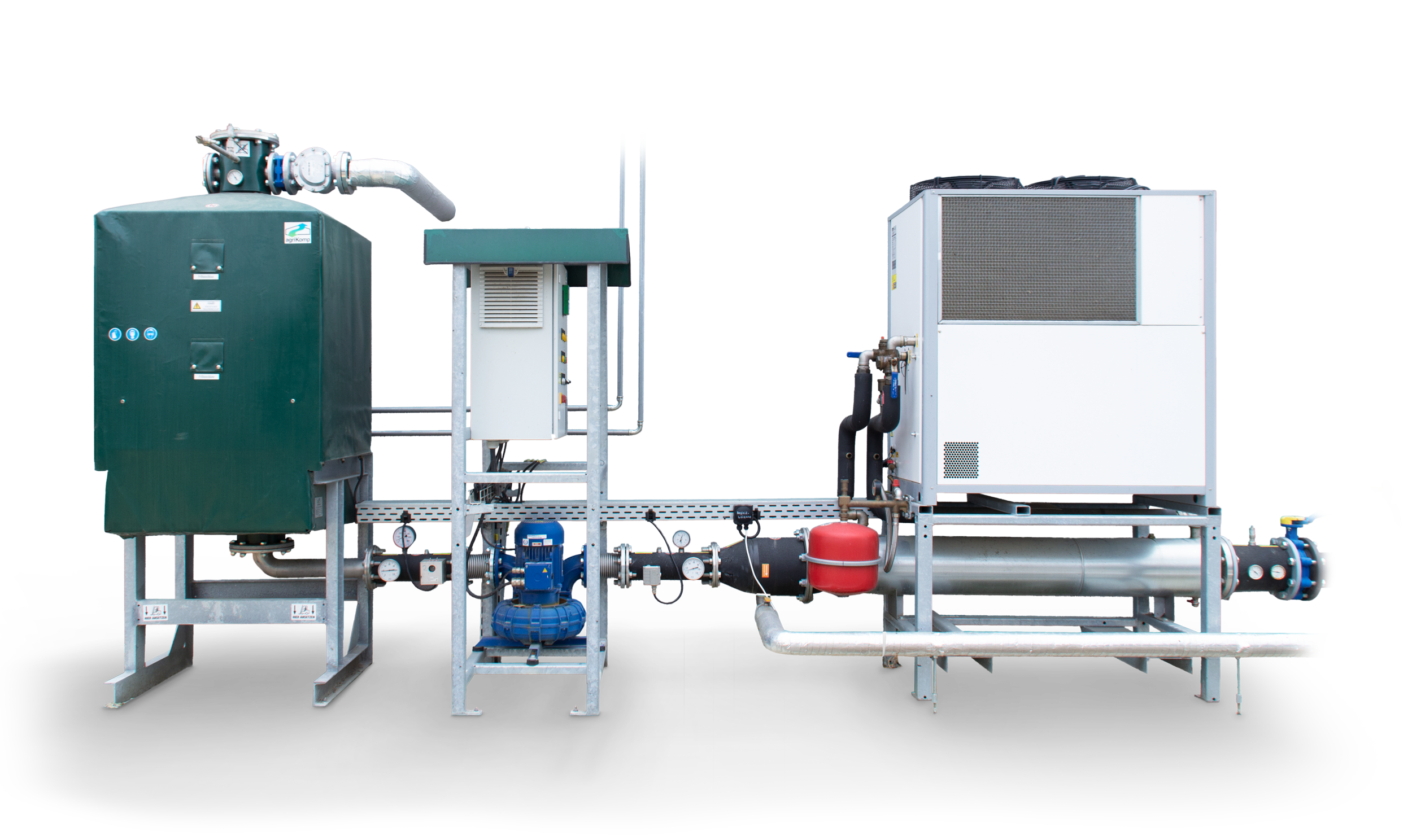

AgriClean 150 – 600

Gas Pre-Treatment

HIGHEST EFFICIENCY –

MAXIMUM CLEANING

The agriClean product range has the function of treating the gas produced in a biogas plant for utilisation in a CHP unit. The gas treatment can be used for the combustion gases biogas, sewage gas and landfill gas. It is designed for outdoor operation, for continuous operation and, with constant flow, also frost-proof.

Cooling module

Cooling of the biogas by separation of condensate

Pressure boosting and control module

Pressure boosting to the required operating pressure

for CHP, control and regulating system

Desulphurisation module

Removal of sulphur compounds and dust particles

Extensions & Service

With many service specialists, we are available to our customers for maintenance and servicing of their CHP on seven days of the week. Above all, technical on-call service at weekends and on public holidays is a matter of course for us and our service partners.

Comprehensive advice by telephone and in person ensures the operational availability of your CHP – unnecessary downtimes in the generation of heat and electricity are thus avoided.

For our qualified employees with many years of knowhow, your CHP unit is the focus of their daily business. Our sophisticated remote maintenance system also enables constant monitoring and evaluation of your CHP – regardless of how many kilometres are in between.

High flexibility and quick reaction in case of emergency – for us more than a promise!

OUR SERVICES – AN END-TO-END CAREFREE PACKAGE!

UPGRADE WITH OUR RETROFIT- & PERFORMANCE KITS

NOX-LOG – NOX- SURVEILLANCE SYSTEM

- Measurement and storage of NOx emissions from CHP units

- Manufacturer-independent surveillance system

- Integration of existing NOx sensors possible

- Supports up to 6 CHPs simultaneously

- Alerts in case of operationally relevant malfunctions or exceeding of critical values

- Simple operation via PC, tablet or mobile phone (network connection)

- Quick and simple installation

Extensions

Expand your CHP with our control components. By using our components for biogas plants, you get the most out of your plant. Keep an overview with our aKCockpit and “Energiepilot”.